1. Introduzione

La Linea guida per i trasporti HACCP intende fornire alle aziende certificate GMP+ FSA (o alle aziende che aspirano alla certificazione GMP+ FSA) un supporto per la realizzazione di sistemi interni HACCP. La linea guida fornisce un esempio interattivo di piano HACCP ed è stata sviluppata in collaborazione con Responsabili della Qualità e Auditor di comprovata esperienza nel settore dei trasporti su strada in diversi Paesi.

La presente linea guida è finalizzata a fornire supporto in materia di assicurazione della sicurezza alimentare e mangimistica ai responsabili e ai dipendenti delle aziende che rientrano nell’ambito del “Trasporto su strada di mangimi” per lo sviluppo di uno specifico sistema interno HACCP. Per la predisposizione del presente strumento HACCP è stata utilizzata come linea guida la descrizione degli HACCP riportata nello schema GMP+ FC 2020 e nel documento S9.4 “Applicazione della valutazione HACCP”. Per ulteriori informazioni sugli HACCP si rimanda al documento S9.4.

Per eventuali definizioni e per la terminologia, fare riferimento a F0.2 Elenco delle definizioni.

Nuttige tip

Il presente simbolo indica la necessità di prestare particolare e specifica attenzione all’argomento in questione.

Scegliere lo schema di Certificazione dei Mangimi GMP+ significa collaborare con la Community GMP+, valorizzando quindi i vostri prodotti e la vostra azienda. Questa scelta garantisce ai cittadini di tutto il mondo mangimi sicuri e responsabili, e di conseguenza alimenti sicuri.

1.1. Campo di applicazione del presente documento

Il presente documento si applica alle aziende (certificate GMP+) che rientrano nell’ambito “Trasporto su strada dei mangimi”, indipendentemente dalla loro tipologia o dimensione, e che si occupano di uno o più aspetti seguenti:

- ordinazione del trasporto di mangimi confezionati e/o alla rinfusa;

- organizzazione del trasporto di mangimi confezionati e/o alla rinfusa;

- trasporto fisico di mangimi confezionati e/o alla rinfusa.

I suddetti compiti possono essere svolti per conto proprio o in qualità di (sub)fornitori (“fornitori di servizi”). Per ciascun compito l’azienda è tenuta a sviluppare e mettere in atto un piano HACCP.

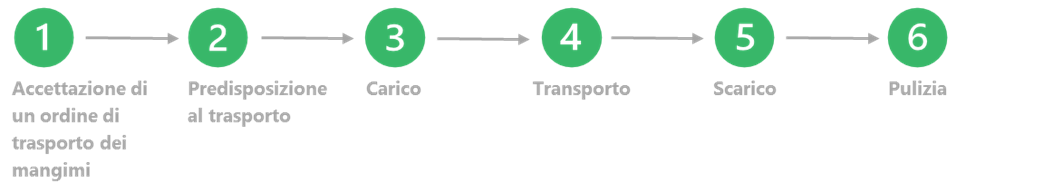

A sostegno delle aziende GMP+ International mette a disposizione un esempio interattivo di piano HACCP (file in formato Excel). Il presente piano HACCP comprende le attività di seguito.

Si tenga presente che è inoltre necessario controllare altri rischi correlati ad attività (che coinvolgono o meno i mangimi) non rientranti nell’ambito della certificazione GMP+. Poiché queste attività possono avere ripercussioni negative sulla sicurezza dei mangimi, è necessario mettere in atto misure di controllo sulla base dell’analisi HACCP e provvedere al relativo monitoraggio. Tutte le attività devono essere ispezionabili/verificabili.

1.2. Trasporto HACCP nell’ambito dello schema GMP+ FC

Ciascuna azienda di trasporto dovrà individuare, esaminare e tenere sotto controllo i pericoli specifici per la sicurezza dei mangimi mediante l’applicazione dei principi HACCP riportati in R1.0. Il documento illustra i rischi più comuni e le relative misure di controllo associate alle diverse attività svolte nell’ambito “Trasporto su strada dei mangimi”. Nel caso in cui si verifichino altri rischi, in particolare quelli specifici al contesto aziendale, anche questi dovranno essere tenuti sotto contro mediante misure di controllo. Le misure di controllo potranno rientrare in un programma di prerequisiti o, in alternativa, l’azienda avrà facoltà di realizzarle come misure specifiche per controllare un determinato Punto di controllo critico.

Si tenga comunque conto che ciascuna azienda certificata GMP+ deve farsi carico della messa in atto del sistema di gestione della sicurezza dei mangimi GMP+, ivi compreso il piano HACCP, in modo corretto e completo, e la stessa è tenuta a darne prova all’atto della certificazione. Le informazioni riportate nel presente documento hanno il solo scopo di fornire delle indicazioni e uno strumento utile all’azienda per realizzare il proprio piano HACCP. GMP+ International non si assume alcuna responsabilità sulla modalità di utilizzo delle informazioni riportate.

2. Istruzione operativa - Come realizzare un piano HACCP specifico per l’azienda

Lo svolgimento di una valutazione HACCP ricade tra gli obblighi e le responsabilità di un’azienda certificata. GMP+ fornisce supporto mediante il presente strumento; l’auditor effettua le verifiche necessarie per attestare la conformità.

Lo schema GMP+ FC è un sistema concatenato. Ciascun anello della catena deve garantire la sicurezza dei mangimi (prodotti) sulla base degli stessi principi esposti nelle norme di prodotto. Il principio fondante che regola l’attività di ogni azienda di trasporto è il trasporto dei prodotti tenendo sotto controllo eventuali rischi e la loro movimentazione garantendo i medesimi livelli di sicurezza prima del carico, durante il trasporto e all’atto della consegna.

Lo strumento HACCP consente di approfondire i rischi presenti durante queste fasi e indica una modalità per tenere gli stessi sotto controllo. Ciascun trasporto avviene in circostanze diverse. Poiché la presente valutazione HACCP ha un carattere generico, la stessa non deve essere utilizzata senza i dovuti adeguamenti. Con ciò si intende l’adeguamento alle circostanze specifiche di ciascuna singola azienda di trasporto. È per questo motivo che lo strumento è interattivo. Le fasi seguenti sono utili per realizzare un piano HACCP specifico per le esigenze di ciascuna azienda. Le informazioni, prese nel loro complesso, rappresentano un sunto del piano HACCP dell’azienda.

Inizio del processo

Fase 1: Esaminare attività e rischi rispetto alla situazione specifica dell’azienda

Per ciascuna fase del processo, valutare in base all’attività (colonna B) se i rischi presenti sulla colonna C si applicano o meno all’azienda.

- Procedere con la fase 2 nel caso in cui il pericolo (colonna C) sia applicabile.

- Cancellare l’intera riga se il pericolo (colonna C) non è applicabile.

- Creare una ulteriore riga se mancano attività. Inserire nella riga aggiunta l’attività mancante (colonna B) e le rispettive informazioni nelle colonne C, D ed E. Proseguire con la Fase 2.

Nuttige tip

I requisiti del cliente hanno un ruolo importante nella fase del processo intitolata “Accettazione di un ordine di trasporto dei mangimi (accettazione del contratto)”. Ricordarsi, quindi, di inserire in tabella gli eventuali rischi legati ai requisiti del cliente.

Fase 2: Individuare la categoria di rischio (colonna H)

Per la definizione della categoria di rischio seguire i passaggi di seguito. Una volta individuata la categoria di rischio, possono rendersi necessarie eventuali azioni (rif. 2.3).

2.1 Definire la Probabilità di occorrenza (colonna F) di ciascun pericolo

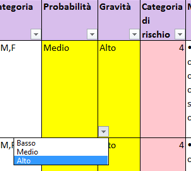

Per ciascun pericolo è necessario selezionare la probabilità di occorrenza.

Quest’ultima dipende dalle circostanze specifiche dell’azienda. Pertanto, è l’azienda stessa a dover stabilire la probabilità di occorrenza. Nel file Excel la probabilità di occorrenza è sempre impostata di default al livello medio. Un menù a tendina consente di scegliere la probabilità di occorrenza tra i seguenti valori: bassa, media o alta.

| Probabilità | Spiegazione |

| Bassa | Possibile in teoria, ma poco frequente in pratica. |

| Media | Possibile: il rischio si è verificato con una certa frequenza. |

| Alta | Il rischio si verifica di frequente. |

2.2 Definire la Gravità (colonna G) di ciascun pericolo

La colonna G riporta un livello di gravità suggerito che l’azienda ha la possibilità di modificare. Un menù a tendina consente di selezionare il livello di gravità pertinente. La modifica del livello deve essere giustificata.

2.3 Definire la Categoria di rischio

Nel file Excel tutte le categorie di rischio sono impostate di default a 3. La categoria di rischio è generata in automatico sulla base della probabilità di occorrenza e della gravità.

| ↓ → | Probabilità di occorrenza | |||

| Bassa | Media | Alta | ||

| Gravità | Alta | 3 | 4 | 4 |

| Media | 2 | 3 | 4 | |

| Bassa | 1 | 2 | 3 | |

Categoria di rischio 1 o 2

I rischi che rientrano nella categoria di rischio 1 o 2 (rif. colonna H in tabella) sono rischi generici che è possibile tenere sotto controllo mediante un programma di prerequisiti. La messa in atto di un piano HACCP prevede il raggiungimento di un livello minimo di controllo della sicurezza dei mangimi. Questo livello minimo si applica anche alle attività di trasporto, indipendentemente dalla rispettiva tipologia ed entità. Il programma di prerequisiti comprende in prevalenza misure di controllo generali, tra cui piani di disinfestazione, piani di pulizia e sanificazione, piani di formazione, piani di manutenzione, procedure per gli acquisti e per la gestione dei reclami. Il programma di prerequisiti fa parte del modulo GMP+ FSA, R1.0, paragrafo 8.2, e TS1.1 Programma di prerequisiti (PRP).

Le misure di controllo generali sono elencate nella colonna J e sono il riferimento per l’applicazione efficace dell’analisi dei pericoli a ciascuna azienda di trasporto. In alcuni casi si rendono necessarie ulteriori misure di controllo. Anche queste misure di controllo sono riportate nella colonna J.

L’azienda dovrà stabilire se le misure di controllo proposte sono sufficientemente adeguate per realizzare con successo il piano HACCP. Se non lo sono, l’azienda dovrà indicare e mettere in atto (ulteriori) misure di controllo che consentano la gestione del rischio.

Per ciascuna misura di controllo, l’azienda dovrà indicare i seguenti dati:

- il soggetto responsabile della misura di controllo*;

- evidenze della misura di controllo**.

* Soggetto responsabile

Inserire un soggetto responsabile per ciascuna misura di controllo (colonna K). Il campo prevede l’inserimento di un ruolo (per es. Dirigente, Responsabile Qualità, Conducente, Addetto alla pianificazione). Nelle aziende più grandi è prevedibile che i vari ruoli siano ricoperti da persone diverse, mentre in quelle più piccole un unico soggetto potrebbe ricoprire più ruoli. In quest’ultimo caso sarà più semplice inserire il nome del responsabile.

** Evidenze della misura di controllo

Inserire le evidenze pertinenti nella colonna L.

Nota Per misura di controllo si intende un’azione in grado di prevenire il rischio (come indicato in colonna H), per es. una telefonata. Si tenga conto che l’azienda dovrà dimostrare l’effettivo svolgimento della misura di controllo.

Categorie di rischio 3 e 4

Quando il prodotto tra gravità e probabilità di occorrenza restituisce un risultato pari alla categoria di rischio 3 o 4, per tenere il rischio sotto controllo sarà necessario adottare una o più (ulteriori) misure di controllo specifiche. Nella colonna J in tabella sono riportati dei suggerimenti relativi a misure di controllo specifiche. Verificare se i suddetti suggerimenti sono idonei per lo specifico contesto aziendale e selezionare le misure di controllo pertinenti.

Se la verifica restituisce un risultato negativo, individuare una o più misure di controllo specifiche e adatte a consentire all’azienda di tenere il rischio sotto controllo (come indicato in colonna H), e infine riportare la proposta nella colonna J.

Passare alla fase 3. L’azienda dovrà individuare in anticipo l’azione correttiva da adottare nel caso in cui si verifichi il pericolo/una determinata situazione (come indicato in colonna C).

Fase 3: Completare il piano HACCP specifico per l’azienda

I rischi con esito riconducibile alle categorie 3 e 4 devono essere tenuti sotto controllo mediante monitoraggio con una determinata frequenza. Se il rischio è fuori controllo, la sicurezza del prodotto trasportato non potrà essere garantita. Per questo motivo è necessario individuare una o più azioni correttive al fine di evitare l’immissione di prodotto non sicuro nella catena mangimistica.

Per tutti i rischi con esito riconducibile alle categorie di rischio 3 e 4, l’azienda dovrà indicare i seguenti dati:

- modalità di monitoraggio;

- frequenza di monitoraggio;

- azione correttiva da realizzare in caso di occorrenza del pericolo*;

- soggetto responsabile dell’azione correttiva**;

- evidenze dell’avvenuta correzione***.

* Azioni correttive

Le azioni correttive sono azioni volte a eliminare la non-conformità rilevata. Tra gli esempi di azioni correttive si possono citare:

- il rifiuto dell’ordine in caso di contatto con un carico non consentito;

- l’arresto delle attività di carico in caso di caricamento del prodotto sbagliato;

- il rifiuto del semirimorchio e la pulizia del vano di carico in caso di (possibile) contaminazione dello stesso allo scopo di ripulire il vano di carico ed eliminare eventuali residui od odori.

In tutti i casi precedenti è necessario informare il cliente e decidere insieme le azioni successive necessarie.

** Soggetto responsabile

Inserire un soggetto responsabile per ciascuna azione correttiva (colonna P). Il campo prevede l’inserimento di un ruolo (per es. Dirigente, Responsabile Qualità, Conducente, Addetto alla pianificazione). Nelle aziende più grandi è prevedibile che i vari ruoli siano ricoperti da persone diverse, mentre in quelle più piccole un unico soggetto potrebbe ricoprire più ruoli. In quest’ultimo caso sarà più semplice inserire il nome del responsabile.

*** Evidenze dell’avvenuta correzione

Inserire le evidenze attestanti lo svolgimento dell’azione correttiva nella colonna Q.

Nota Per azione correttiva si intende un’azione in grado di eliminare il rischio, per es. una telefonata. Si tenga conto che l’azienda dovrà dimostrare l’effettivo svolgimento dell’azione correttiva.

Nel caso in cui si renda necessaria l'adozione di un’azione correttiva, valutare subito se migliorare o meno il processo e le misure di controllo (indicati nella colonna J) per evitare il ripresentarsi del rischio. Tutte le azioni correttive devono essere riesaminate con cadenza almeno annuale (R1.0, paragrafi 8.6.2.2 e 9.3).

Fase 4: Aggiornare il piano HACCP

Tutte le informazioni fornite nelle fasi da 1 a 3 rappresentano un sunto del piano HACCP dell’azienda. Il piano HACCP deve essere aggiornato. Il riesame deve essere effettuato almeno una volta all’anno e a seguito di modifiche rilevanti. Esempi di modifiche rilevanti comprendono:

- variazioni nei ruoli aziendali (rif. 1.1);

- variazioni nelle attività svolte dall’azienda;

- necessità di adottare delle azioni correttive.

- Il database IDTF deve essere aggiornato in caso di introduzione di nuovi prodotti o regimi di pulizia.

Si rimanda a R1.0, paragrafo 10.3, per i requisiti specifici relativi all’aggiornamento del piano HACCP.

Nuttige tip

- Vanno favoriti il pensiero critico e l’apertura: il personale deve sentirsi libero di segnalare eventuali errori per consentire all’azienda di adottare le misure di controllo necessarie (per es. formazione). Il personale deve essere formato a segnalare e riportare eventuali problematiche.

- Per rilevare l’efficacia delle misure di controllo utilizzare i reclami.

Risk Management tools

Where to find more about the Risk Management tools? Fact sheets More information: GMP+ Platform Product list More information: Product List Risk Assessments More information: GMP+ Platform GMP+ Monitoring database More information: GMP+ Monitoring database Support documents More information: Support documents |