1. Introduction

This document is meant to provide information and explanation to the GMP+ community about the background, scope and practical implementation of the GMP+ transport requirements. This document addresses the most frequently asked questions and is intended as a guide to the companies involved in GMP+ transport.

Should you have any further questions or would like to receive more information, you can always contact us via our contact form. If necessary, this document will be expanded.

The topics are clustered as follows:

- Road transportation

- Inland waterway transport and short sea shipping

- Sea transportation

- Rail transportation

- Purchase

- Certification

- Other

2. Road transport

2.1. What to do if I cannot obtain a confirmation by the local authorities for transport of Cat. 3 products?

Regarding the transport of Cat.3 products, legislation requires confirmation by local authorities. The problem is that this confirmation is hard to obtain in some countries.

GMP+ FC scheme respects and accepts the interpretation and way of working of local authorities regarding this legislation. Where loading compartments used to transport Cat3 products are covered under the scope of GMP+ certification, as a minimum the transport company which is faced with this problem must have put demonstrable effort into obtaining this confirmation.

But an option to avoid this problem is to dedicate specific loading compartments for the transport of Cat.3 products and to exclude these loading compartments from the scope of GMP+ certification. In this way, the GMP+ requirements, including the requirement to obtain this confirmation from local authorities, are not applicable to these specific loading compartments.

This specifically relates to products covered under the scope of Reg. (EC) no. 999/2001.

2.2. Do tractionairs also have to be certified?

Yes, tractionairs also need to be certified. Note that a tractionair is defined as: a tractor & driver (GMP+ B4, F0.2). A tractionair (traction unit) is regarded as a separate legal entity. The rationale for this separate certification is that the activities of a tractionaire regarding transport are not limited to just transporting a loading compartment from A to B. Tractionaires are also responsible for other important transport activities like cleaning and registration.

See also GMP+ B4 §7.1.1, / TS1.2§3.6. where this is laid down:

| Tractor | Traction unit (tractional) | Driver | Loading compartment |

| No requirements | Certified: Appropriate instruction provided | Training in accordance with GMP+ requirements | Certified: |

| | Not certified: only for sealed loading compartment | | Not certified: release procedure specified in Procedures GMP+ International section on the IDTF website . |

There is not a separate GMP+ certification scope for tractionairs. They are all certified under the Road Transport of Feed scope. However, GMP+ FC scheme has defined 2 types of tractionaries:

- Tractionaires with their own FSMS and

- Tractionaires that are included in the FSMS of their principal (client).

- Tractionaires with their own FSMS

Where the tractionair is operating with its own FSMS, GMP+ FC scheme concludes that it is operating as a road transport company – because it handles its own transport orders, training, internal audit.

Tractionaires with their own FSMS can carry out feed transports for different clients.

- Tractionaires that are included in the FSMS of their principal (client)

Most tractionaries are included in the FSMS of their principal. This is comparable to multi-site certification. In the GMP+ companies' database, these tractionaires are linked to their principal. These tractionaries carry out all the transport of feed for the principal exclusively.

Please contact the certification body for details.

In some circumstances, certification is not required for a tractionair. See 2.5.1.

2.3. Sealed containers: which requirements apply?

In this topic, a few aspects of sealed containers are explained.

2.4. Which requirements apply for sealed containers?

The container must be properly sealed (it cannot be opened without breaking the seal). The seals must be complete and intact. There must be clear information about the total number of seals and their identification numbers.

2.5. What are the requirements for companies that rent containers?

The GMP+ FC scheme does not establish any requirements for companies that rent containers. This responsibility lies with the GMP+ certified producer/trader who arranges a container. This company should treat that container as packaging. In practice, this means that the GMP+ certified producer/trader must decide, based on a risk assessment, whether the container is suitable for putting the feed in.

Please see for the requirements for packaging:

- GMP+ B1 §6.3.2.4 Other facilities

- GMP+ B2 §5.2.4.5 Packaging

- GMP+ B3 §5.2.4 Other requirements

- TS1.10 §1.6 Packaging

In order to be able to make the risk assessment, the GMP+ certified producer/trader must receive sufficient information about the previous loads and cleaning regimes from the company that rents the container. The classification of products in IDTF can be used as guidance for the risk assessment.

2.5.1. What are the requirements for companies that transport sealed containers?

If the container is arranged and managed by the principal (GMP+ certified producer/trader) and the transport company has no influence on the transported feed, then the transport company does not have to be GMP+ certified. See for details 2.5.2.

If the containers are the property of the transport company, it is reasonable to expect that the transport company will have control over these containers (at least to the certain extent). The containers are then considered to be regular loading compartments and the transport company must comply with the regular GMP+ requirements, including certification in the case of bulk transport.

2.5.2. When is a sealed container considered to be a packaged product?

A sealed container is considered to be a packaged product when the container is properly sealed (it cannot be opened without breaking the seal). The loading compartment is under the management of a GMP+ certified producer or trader that must:

- manage the cleaning and inspection of the loading compartment

- close and seal the loading compartment

The non-certified external carrier has no influence over the transported feed. The non-certified external carrier may not use its own loading/unloading equipment (pipes, hoses, etc.) unless permitted to do so by the GMP+ certified producer or trader.

For the requirements referred to above, please see:

- GMP+ B1 §4.1 Requirements for the feed safety management system

- GMP+ B2 §7.7.3 Road transport carried out by subcontractors

- GMP+ B3 §7.3.3 Road transport carried out by a subcontractor

- TS 1.2 §3.6

- F0.2 Definition list

2.5.3. Not every sealed loading compartment is considered to be a packaged product

If a loading compartment belongs to a transport company and is managed (tracking and tracing, cleaning, inspection) and used by that transport company, this loading compartment - even if sealed - is not considered to be a packaged product. In that case, the regular scheme requirements apply.

2.6. What are the points of attention when using the services of a cleaning station for cleaning the loading compartments (B4 §7.3.2 / TS1.9 §4.1)?

Note: there is an ongoing discussion about criteria for cleaning stations. The aim is to define better quality criteria for the cleaning service. But in order to evaluate whether a cleaning station meets your feed safety requirements, you should pay attention to the following points:

- What is the quality of the water used for the cleaning?

- Is there continuous monitoring during the cleaning process?

In general, if there is no continuous monitoring during the cleaning process, it is impossible to guarantee that the cleaning process in practice is the same as stated on he cleaning certificate.

- What kind of guarantee do you get from the cleaning station: a best-effort obligation or the obligation to provide the requested results?

- How is the cleaning inspection organized?

Note: a visual inspection through manholes is limited to only the area that was easily visible from the manhole. What about the critical areas that may not be easily visible but need to be inspected? - What kind of information is provided on the cleaning certificate?

Besides clear identification of the loading compartment (eg number plate of the trailer, ID of the container, etc.) and date and time of the cleaning, the cleaning certificate should at least provide a detailed description of all the process steps of the cleaning program carried out for that loading compartment and the attachments:- last forbidden load

- order and selection of cleaning regime

- preparation/emptying of loading compartment

- pre-wash, main wash, rinse, including information on

- the duration of each step

- the water temperature

- the name of the cleaning/disinfection agent

- the concentration of the cleaning/disinfection agent

- cleaning of pumps, accessories and attachments must be explicitly stated if done

- drying, assembly and documentation

- cleaning inspection, including the specific information on inspection of baffles, pumps, accessories and attachments if done

- total duration of cleaning (start time and end time)

As part of the assessment of the suppliers, according to the FSMS at least an annual re-assessment must take place reconfirming the list of qualified suppliers.

Note: If for whatever reason the cleaning station does not provide you with a cleaning certificate with sufficient information about the cleaning, the company may draw up a pre-completed statement with all the necessary information, to be signed by the cleaning station. By signing, the cleaning station confirms proper cleaning. The content of this statement should at least cover the topics above.

Otherwise, a statement of food grade cleaning procedure could be included in the certificate or in another related document like a service order, order confirmation, agreement signed with the participant, etc.

2.7. What are the options for re-using a loading compartment after a forbidden load has been transported by accident?

In general, the transporter has two options for releasing a loading compartment after the transport of a forbidden load (so-called release procedure):

- Cleaning the loading compartment, accessories and attachments by the transporter himself, followed by inspection of the loading compartment by an independent control organization or certification/inspection body.

- Demonstrable cleaning by an external cleaning station (see 2.7 for the requirements for the cleaning certificate), followed by the loading compartment inspection by the GMP+ certified producer/trader who will load the next GMP+ load into the loading compartment.

Besides the options listed above, for some products (eg processed animal proteins), the competent authority may require a specific release procedure.

For detailed information about the release procedure, see the IDTF website, “Procedures” section and TS1.9, Appendix.

2.8. How can a check on the effectiveness of cleaning regime and disinfection be carried out (B4 §7.3.2.1/ TS1.9 §4.1)?

Firstly, some general points about validation and verification. When you start using a cleaning regime for the first time, in a certain type of the loading compartment, you have to prove and confirm that the way you clean will result in effective cleaning.

The cleaning regime includes not only the means of cleaning (brushes, brooms, mops, disinfectants, detergents, etc.) but also how you use them to clean and how much you use. When you have defined all of the above elements of a cleaning method and have proof that these results in proper cleaning, you have validated the cleaning regime.

From now on, you can trust that if you carry out this cleaning regime in that specific type of the loading compartment, in the same way, using the same means, with the same amount of water or detergent every time, this will result in clean cleaning. From now on, you only need to check this once in a while

More specifically about cleaning regimes A, B, C and D, which are defined in the GMP+ FC scheme:

| Cleaning regimes A and B | |

| Background information | Cleaning regime A is applied in the case of transport of dry products. Cleaning regime B is applied in the case of vapor, sticky or liquid products which are all soluble in water. Nevertheless, places that are difficult to reach should if necessary be cleaned separately with additional means such as brushes. It is important that the water can be drained. Products classified with either cleaning A or B have in common that the (micro)biological and chemical risk is low. These products do not contain pathogenic micro-organisms, there are no indications for or perceivable signs of poor storage conditions or decay and animal products forbidden in animal feed are not present. Chemical products classified with cleaning regimes A or B are assessed as harmful only at high doses. The MSDS indicates LD50 > 5000 mg/kg of bodyweight for oral administration in rats. |

| Validation | In view of the nature of the products, both validation and verification could be carried out by visual inspection only. |

| Verification | |

| Cleaning regime C | |

| Background information | Cleaning regime C is applied in the case of products containing protein or grease. They are not soluble in water or have LD50 < 5000 and > 50 mg/kg of bodyweight for oral administration in rats. For this kind of cleaning, the right combination of duration of cleaning as well as rinsing, water temperature and correct application of the cleaning agent (which kind is used, where it is applied, how long it is applied for and in what concentration) are essential for the effectiveness of the cleaning regime. |

| Validation | In view of the nature of the products classified with cleaning regime C, proper validation requires that the additional checks need to be carried out, taking into account the nature of the transported product. In order to assess the cleaning after transport of organic products, ATP (Adenosine Tri Phosphate) measurements can be used. More advanced methods may be used to check for chemical residues and pesticides, such as HPLC and Mass Spectrometry (MS) of the last rinsing water. In all cases, attachments and accessories, such as hoses and pumps, must also be included in the validation. |

| Verification | Verification can be done by visual inspection. |

| Cleaning regime D | |

| Background information | Cleaning and disinfection (D) is applied when preceding loads are microbiologically unacceptable (detectable signs of decay), or if it is known that they carry micro-organisms that cause disease, such as Salmonella. |

| Validation Verification | As microbiological contamination cannot be detected by visual inspection, both validation and verification must be done by means of additional checks which can determine the numbers of surviving micro-organisms, such as agar stamps. |

2.9. What information should be in the logbook or immediately available?

The company responsible for the transport of feed must retain as documented information:

- the successive transports; the cleaning regimes between successive transports; inspections and checks;

- bulk transport in a journey sheet:

- loads per loading compartment – preferably with an IDTF number; (nature – not the trade name of loads)

- the cleaning regimes performed after the transport of those loads.

The company responsible for the transport of feed must have available for inspection:

- the journey sheet for the loading compartment

- the registration of the previous three loads (including cleaning regimes) in that loading compartment, provided with the date and a signature from the company responsible for the transport of feed.

Nowadays, different registration systems are available, both analog and digital. Information can therefore be made available via:

- a logbook completed by the drivers and kept on board, or

- issuing it and sending it by logistic department at least before the service is supplied

In the case that information is NOT kept on board Information, the information must be immediately available or retrieved.

2.10. Inspection by transport company before loading (B4 §7.3.3/TS1.9 §3.2.1)

Are the inspections as described in A and B (see below) applicable for GMP+ certified transport companies?

- The inspection prior to loading the truck is the responsibility of the transporter. The inspection before the transport of feed must be documented by the driver.

- If the load carried immediately prior to the new transport operation consisted of the same type of feed as that to be transported and the feed was of perfect quality, the inspection may be waived.

Answer A: Not necessarily. When accepting the transport, the company responsible for the transport of feed must confirm the Loading compartments cleanliness clause. By means of this clause, the company declares that it is supplying the loading compartments clean, empty, dry (if necessary) and free from undesired odors. It is up to the company to organize this internally. The inspection can be performed immediately after the cleaning or prior to driving to the loading location. In any event, the company responsible for transport must be able to guarantee that at the moment of loading, the loading compartments comply with the Loading compartments cleanliness clause.

Answer B: For this question, see 2.13.

2.11. Do I have to clean after the transport of each product?

No, a loading compartment must be cleaned before any transport of GMP+ assured feed. However, there are some situations when the cleaning as laid down in the IDTF can be waived, for example:

- If an exception for the cleaning is established in the IDTF

- In the event of consecutive transport of the same feed material, under strict conditions. For this question, see 2.13.

- In the event that the next product to be transported is packaged GMP+ assured feed (or equivalent)

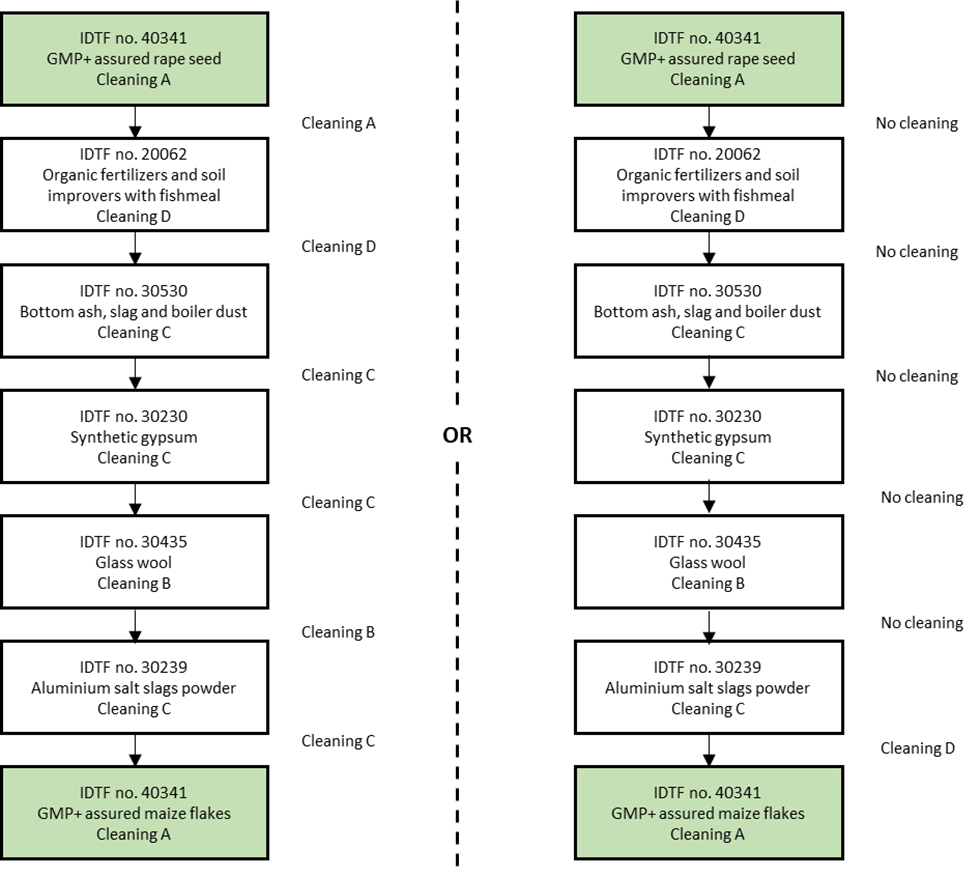

Cleaning between transports of non-feed products is therefore not necessary. Nevertheless, the transport company must determine and document (eg in the planning software) the cleaning regime for non-feed products. The strictest of these cleaning regimes must be carried out before the loading compartment is loaded with GMP+ assured feed again. The figure below shows some examples of the moments when cleaning is required between consecutive transports of feed and non-feed products.

2.12. Which cleaning regime applies between two transports of the same feed materials of vegetable or mineral (inorganic) origin?

A loading compartment must be cleaned before any transport of GMP+ assured feed. In a strict interpretation of this GMP+ requirement, a prescribed cleaning must also take place between transports of feed materials.

For some groups of feed materials there is already an exception from cleaning established in the IDTF (see also 2.12). However, in practice there is also often no cleaning between transports of the same feed material (for example wheat-wheat). Also in the case of bulk transport of the same liquid feed material, experience shows that cleaning is not necessary.

Cleaning after transports of the same feed materials is not mandatory, or can be done with a different frequency, when the following requirements are met:

- The next load contains the same feed material of vegetable or mineral inorganic origin;

- The bulk loading compartment has been emptied properly/the bulk tanker has been properly drained;

- This exemption from cleaning must be approved in writing by the company that receives the feed material. The instructing party must confirm to the transport operator that the exemption can be applied;

- This exemption must be included in the risk assessment of the transport company and documented. It must not lead to an increase in chemical, microbiological and/or physical risks for transported feed, nor to a risk of carry-over of GMOs. The time between the next two transports must also be taken into account.

- When switching to another feed material, the prescribed cleaning regime must always be carried out.

2.13. What does cleaning regime A mean for a bulk tanker?

Cleaning regime A means dry cleaning of the loading compartment. This can be done in different ways as long as the loading compartment is completely emptied, for example by using a brush, floor squeegee or blower system. For liquids, total drainage is also considered to be dry cleaning.

2.14. What is the minimum cleaning regime after transport of liquid compound feed?

There are many different kinds of compound feed. In the IDTF database, compound feed without processed animal proteins and/or veterinary drugs is classified as requiring at least cleaning regime A. Please note that this relates to the minimum cleaning regime. If after carrying out the minimum prescribed cleaning regime the loading compartment is not yet clean, then cleaning should be performed again with an effective cleaning procedure. This could be the case when, for example, liquid compound feed is transported, or when the loading compartment is equipped with a walking floor system.

2.15. Why are some loads which are forbidden for road transport permitted for inland waterway transport?

In the case of inland waterway transport, there must always be an inspection of the loading compartments (LCI) after cleaning and before loading with feed. This inspection must be performed by an independent external official control organization or loading inspector. Thanks to this independent check on the cleaning, barges are permitted to transport some loads which are considered too risky for road transport.

3. Inland waterway transport and short sea shipping

3.1. What do I need to pay attention to when painting / coating loading compartments?

On the one hand, painting/coating protects the loading compartments against rust, wear and aggressive components/substances in cargoes. On the other hand, it makes the surface smooth, which makes the loading compartment easier to clean and means it will dry more quickly.

The paint/coating must not represent a risk to the safety of feed.

- If you see loose pieces or flaking paint/coating, remove them as quickly as possible. Otherwise, there is a risk that they will end up in the feed, causing it to become contaminated.

- The paint/coating must be food grade. This means that it is suitable for use on surfaces which come into contact with food and/or feed. Check this carefully. If this information is not shown in the instructions for use, read the technical data sheet (for example, MSDS – material safety data sheet) or contact the supplier of the paint/coating. Store this information carefully in case you receive questions about it during the GMP+ audit/inspection.

- Check carefully how long the paint/coating needs to dry before it is completely usable (in other words not just touch dry/tack-free or overpaintable).

Please note : paint/coating is only food grade if you strictly adhere to the drying times specified by the manufacturer.

Due to differences in ambient temperature and humidity, it can sometimes take longer before the paint/coating is completely usable. Keep this in mind when planning maintenance/transport.

3.2. I have transported a forbidden/non-classified product in my dry cargo vessel. Do I need to initiate a release procedure immediately after unloading?

An immediate release procedure is only compulsory if you want to transport feed immediately afterwards. In this case, you should first initiate the release procedure, as described in Work Plan 9c.

It does not matter how many non-feed cargoes you have already transported after transporting the forbidden/non-classified product.

If no feed is transported after transporting a forbidden/non-classified product, but instead, for example, sand, coal, scrap metal, etc., you can delay the release procedure.

But please note: if you delay the release procedure, there is a risk that you may forget it completely. This can happen if you do not often transport feed. Such an omission may go unnoticed during a Loading Compartments Inspection, because details will only be requested about the previous three cargoes. During the GMP+ audit, the auditor/inspector looks back much further at the products transported. A missing release procedure before loading with feed will be regarded as a serious shortcoming that can result in the loss of your GMP+ certificate.

If you nevertheless decide to delay the release procedure, it is important that you devise a system for yourself so that you do not forget to initiate it at a later date.

3.3. I have transported a forbidden/non-classified product in my tanker vessel. Can I also apply the release procedure described in Work Plan 9c?

No, this is not permitted – the procedure in Work Plan 9c is only for dry cargo vessels. The GMP+ FC scheme does not have a release procedure for tanker vessels. This means that only dedicated GMP+ feed tanker vessels may transport GMP+ feed. No products other than products for the food and/or feed industry may be transported.

The GMP+ FC scheme strictly adheres to the Inland Waterways Hygiene Code. If you have loaded products in your tanker vessel other than products for the food and/or feed industry, drastic measures are required to make the tanker vessel suitable for feed transport. These include replacing all piping, coils and pumps that may have come into contact with the cargo. In addition, the loading compartments, boiler and slob tanks may also need to be replaced. For a detailed description, see Work Plan 9a. Store the proof of the measures taken carefully because you may be asked for it during the GMP+ audit/inspection.

It is therefore also important when purchasing a second-hand tanker vessel that you establish whether the vessel has exclusively been used to transport products for the food and/or feed industry. Store the proof to this effect as documented information in case you receive questions about it during the GMP+ audit/inspection.

4. Sea transport

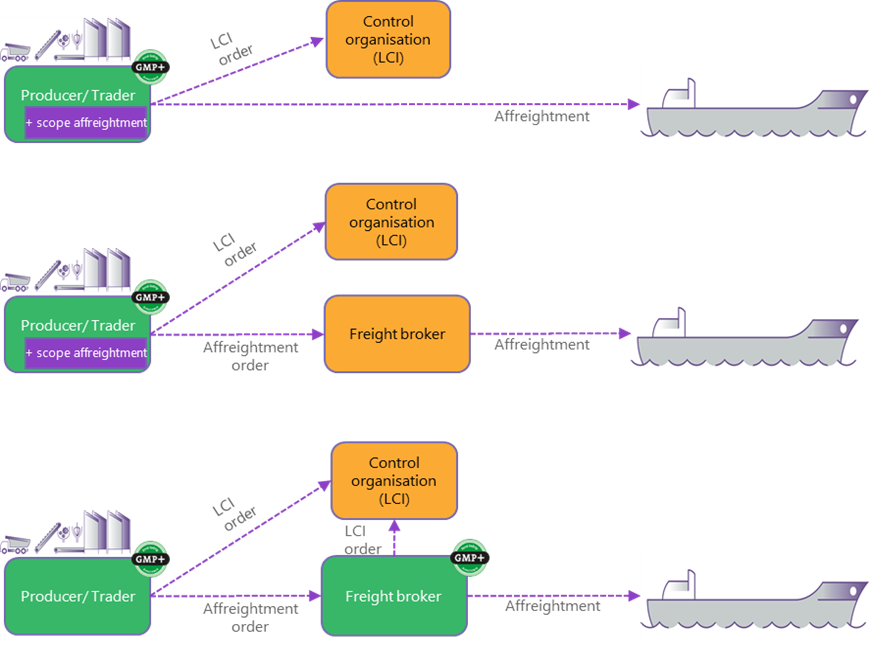

4.1. What are certification requirements for GMP+ certified traders and producers involved in transport by seagoing vessel?

A GMP+ certified producer or trader (principal) that wants to have GMP+ assured feed transported by seagoing vessel must:

- either engage a freight broker that is GMP+ certified with the scope: affreightment of sea transport (GMP+ BA10 §3.7, R1.0 §7.1.5, TS1.2 §3.7)

- or be GMP+ certified itself with the scope: handling of sea transport (GMP+ B1 §4.1, B2 §7.7.5, B3 §7.3.4, R1.0, §4.3)

Every transport of feed by seagoing vessel must be preceded by a loading compartment inspection (LCI) of the seagoing vessel. An order for the LCI must be issued by a GMP+ certified company: a GMP+ certified producer/trader (principal) or a GMP+ certified freight broker.

The LCI can be carried out by a loading inspector from the control organization. It is important here that the company that carries out the afreightment is not allowed to carry out the LCI itself (GMP+ B4 §7.2.3, TS1.9, §3.2.2).

See also the figure below.

Figure: Possible arrangements between the principal and the freight broker

4.2. May I use so-called combination carriers for the transport of feed bulk?

Combination carriers are seagoing vessels which can convert from tanker mode to dry-bulk mode and vice-versa.

When these combination carriers are also used for the transport of non-food/non-feed products, they can in general be suitable for the transport of dry feed bulk. In that case, only loading compartments are used (so not the pipes, pumps, boilers, etc.). However, the decision on whether the loading compartment is suitable for the transport of dry feed bulk is the responsibility of the GMP+ certified freight broker (generally a GMP+ certified producer or trader who organizes transport by seagoing vessel).

In GMP+ B4, §7.2.1 and TS1.9, §3.1 it is laid down that when accepting an order for the transport of feed by sea, the freight broker may draw up criteria with respect to previous loads on the basis of risk assessments . The previous loads and the cleaning regimes used must be assessed with respect to feed safety in connection with the carrying out of animal feed transport.

To perform the risk assessment, the GMP+ certified freight broker needs to gather some information. For example:

- Obligatory: nature/name of at least the three previous loads (liquid/dry bulk) transported in the relevant loading compartment.

Points of attention:

- Some food/feed schemes and associations forbid Dirty Petrol Products (vacuum gas oils, crude oil, fuel oil, dirty condensates) and certain chemicals as immediate previous loads for liquid feed bulk. This can be an indication to refuse these products as immediate previous loads for dry feed bulk too.

- Obligatory: description of the last three cleaning regimes carried out on the relevant loading compartment.

Points of attention:

- If cleaning agents are used, are they food grade?

- Are fittings, inlet mouths, thermometers, coils and such properly cleaned?

- Is the smell of the previous loads removed during the cleaning (a particular point of attention for liquid previous loads)?

- Are there analyzes available to support the efficiency of the cleaning regime (eg wall wash test/spectrometer analysis of the last rinsing water, etc.)?

- Has the shipowner made a risk assessment for the transport of dry feed bulk after the transport of non-food/non-feed products in that specific combination carrier, with a focus on feed safety? If yes, is it available to you?

- Is the vessel equipped with stainless steel loading compartments? If not, is the loading compartment coated?

Points of attention:

- Is the coating used in the loading compartments food/feed grade?

- Are there measures to prevent the cargo penetrating the coating (eg timely repair of blisters, cracks, flakes)?

- Are there measures to prevent leakage of any residues of liquid previous loads into dry feed bulk segregation (eg (double) or blinding of all lines leading to loading compartments, positioning of the inlets in the loading compartments, cleaning and sealing of the inlets in the loading compartments, timely replacement of any rubber seals, etc.)?

Practical implementation of some of the points mentioned above may be checked during the loading compartment inspection.

5. Rail transport

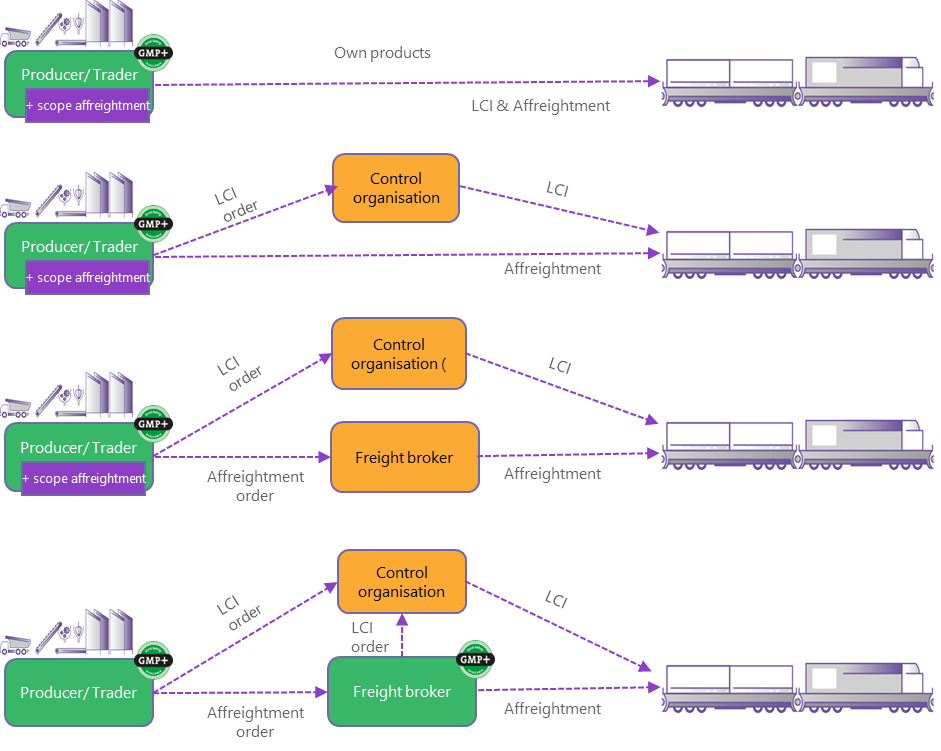

5.1. What are certification requirements for GMP+ companies involved in rail transport?

GMP+ certified producers and traders

- A GMP+ certified producer or trader (principal) that wants to have GMP+ assured feed transported by rail must:

- either engage a freight broker that is GMP+ certified with the scope: affreightment of rail transport (R1.0, par. 7.1.5, TS1.2, par. 3.7).

- or be GMP+ certified itself with the scope: handling of rail transport (R1.0, par. 4.3)

- If GMP+ certified producer or trader transports assured feed with its own (owned, rented or leased) rail wagons, the company must be certified for rail transport or feed.

GMP+ certified freight companies

Affreightment company/ freight broker is a company that entirely or partly arranges/organises the transport of animal feed by rail transport. This on behalf of and at the expense of the GMP+ certified company.

- See GMP+ certified producers and traders

- A GMP+ certified producer/trader, that is certified with the scope affreightment of rail transport, can subcontract a non-certified freight broker to assist in finding suitable wagons. However, the GMP+ certified producer/trader remains entirely responsible for the clearance.

- External freight broker that arranges/organises the transport of packaged animal feed (eg in big bags - see F0.2 Definition list or containers) does not have to be GMP+ certified.

See also the figure below.

Locomotives and wagons

- Locomotives

The traction units/locs are not part of the GMP+ chain and need no GMP+ certification. Locomotive drivers do not need to be trained for specific GMP+ knowledge.

- Wagons

- GMP+ certification is currently not mandatory for rail transport for external rail companies.

- The lessor of wagons does not have to be GMP+ certified.

- The GMP+ company who owns, rents or leases wagons must bring the transport by rail under the GMP+ certification scope.

- GMP+ certification does not apply for intermodal transport (with containers) on flat wagons.

5.2. What are the specific requirements for wagons?

- Transport of GMP+ assured feed must find place in 'agri-only' rail wagons - see F0.2 Definition list (TS1.9, par. 2.a.).

If no 'agri-only' wagons are available, the procedure for release must be applied to obtain admission of a wagon for transport of feed. The release procedure is specified in the TS1.9, Appendix iii-c or on the IDTF website/ Procedures tab/ GMP+ International. (TS1.9, par. 4.1a)

- Covered wagons, in general freight compartments, such as category Ta.., Ua…, etc or specially built containers (eg bulk containers) which are preferably used for the transport of bulk goods, moist goods but also liquid products have to guarantee that they protect the shipment against the effects of weather, loss or theft.

- However, the design of the cargo compartment, where it comes into contact with the product, has to be constructed in such a way that no contamination can result from the materials used in its construction. This information can be obtained from the wagon keeper.

- When loading compartments or parts of the loading compartments are painted or coated, then the applied paint or coating must be suitable for food contact, meaning food safe coating, solvent free. (TS1.9, par. 4.2.1.a). Check this carefully. If this information is not shown in the instructions for use, read the technical data sheet (for example, MSDS – material safety data sheet) or contact the supplier of the paint/coating. Please note: paint/coating is only food grade if you strictly adhere to the drying times specified by the manufacturer.

5.3. What are the points of attention concerning load compartment inspection (LCI) of wagons?

- Every transport of feed by rail must be preceded by a loading compartment inspection (LCI) of the wagon. An order for LCI must be issued by a GMP+ certified company: GMP+ certified producer/ trader (principal) or a GMP+ certified freight broker.

- The wagons must be empty for the inspection. Every wagon must be checked. (TS1.9, par. 3.2.3).

- The LCI can be carried out by a loading inspector from the control organization or by a loading inspector from a GMP+ certified company (mostly supplier). It is important here that the company that carries out the afreightment is not allowed to carry out the LCI itself. (TS1.9, par. 3.2.2).

The only exception are GMP+ certified producers/traders who are arranging the transport of their own feed by rail wagons. These companies may carry out the LCI themselves. (TS1.9, par. 3.2.2).

See also the figure below.

5.4. What are the points of attention concerning cleaning of wagons?

- Points of attention for verification of rail wagons are: interior, top covers, stair doors and appurtenances.

- The International Database Transport (of) Feed (IDTF) contains the requirements relating to transport sequence and the cleaning and disinfection regimes for a large amount of products. The cleaning regimes as laid down in the IDTF do not apply for the cleaning of agri-only wagons. When using agricultural-only wagons, the loading compartments must be broom clean/ properly drained. When the wagons are broom clean / properly drained an extra cleaning is in most cases not necessary. This depends on the product and additional customers' requirements. For example a transport of organic feed and GMO products will require some extra arrangements in your FSMS. The GMP+ company responsible for feed-safe transport, must draw up a risk-based cleaning schedule. (TS1.9, par. 4.1)

Note: In the railway sector, the availability of cleaning equipment, especially for wet cleaning, is very limited. Transporting products for which broom cleaning is sufficient is therefore the most practical option. However, you cannot rule out the possibility that occasionally a wet cleaning is needed, for various reasons. This usually has to be carefully planned in advance and causes additional costs and binds time resources.

- The lessor of the wagons must ensure clean loading compartment. It is important to know which previous loads have been transported and which cleaning regimes have been carried out. At least the last previous load and the last cleaning must be known (TS1.9, par. 3.2.1 and 4.3)

- If the wagons are not completely empty, or are contaminated, the loading company will contact the principal. The locomotive driver does not fulfill any role or responsibility in the cleaning, verification, signing the LCI – report or signing for the cleaning performed.

- The International Database Transport (of) Feed (IDTF) contains the requirements relating to transport sequence and the cleaning and disinfection regimes for a large amount of products. The cleaning regimes as laid down in the IDTF do not apply for the cleaning of agri-only wagons.

5.5. What information must be registered for traceability purposes?

For GMP+ FC scheme the following must be registered (R1.0, par. 8.3 and TS1.9, par. 4.3):

- wagon numbers

- data of loading and unloading location, product, status or GMP+ service

- details of the operator of the rail wagons

- last cargo (preferable: last three cargos)

- last cleaning regime (preferable: after last three cargos)

- where necessary: seal number

Figure: Possible arrangements between the principal and the freight broker

6. Purchase

6.1. What are the requirements for communication about the status of the transport service provided?

A GMP+ certified company must always make clear to the provider of transport services that the transport must be GMP+ assured or equivalent. This requirement is laid down

- GMP+ B1 §7.10.2 d

- GMP+ B2 §7.1.2

- GMP+ B3 §7.1.2.1

- R1.0 §7.1.5 b

Note: In R1.0, this is laid down in a more general way: the certified company must ensure adequate communication about requirements/wishes to external supplier(s)

On the other side, the certified transport service provider must make the status of the delivered service clear to the customer. This must be done using a positive declaration for all services assured under its GMP+ Feed Safety Management System.

This requirement is laid down

- GMP+ B4 §7.2.1

- R1.0 §7.4.2., a) 2)

There should be clear evidence that the service was GMP+ assured at the time of delivery. The certified transport service provider can issue this positive declaration in the order confirmation e-mail, on the contract (for year-round services), on the invoice, or in some other written form.

6.2. What does the requirement that the company responsible for transport must have at least a documented procedure for accepting an order for the transport of feed mean?

In GMP+ B4 §7.2.1 / TS1.9 §3.1, the requirement is laid down that the company responsible for transport must have at least a documented procedure for accepting an order for the transport of feed.

This means that such a procedure is only required for the transport of feed products. There is no need to set up a special procedure for accepting an order for the transport of non-feed products (eg sand, wood, chemicals).

Although a special procedure is not required, for non-feed products, too, the company must determine and document (eg in the planning software) the nature of the product and the cleaning regime according to the IDTF, preferably with the IDTF number. This must be done for each loading compartment that falls under the FSMS of the company. In this way, the company will know how to clean the loading compartment before the next transport of GMP+ assured feed in that loading compartment.

For some examples of the moments when cleaning is required between consecutive transports of feed and non-feed products, see 2.10.

The cleaning which is actually carried out should be registered in the logbook.

7. Certification

7.1. I am a GMP+ certified producer/trader. Do I have to be certified for the scope road transport if I occasionally transport packaged feed?

Yes you do. The option of purchasing transport of GMP+ assured packaged feed from a non-certified transport company must not be interpreted as meaning that you can exclude your own transport of GMP+ assured packaged feed from the scope of your Feed Safety Management System and from certification: your own transport of GMP+ assured packaged feed must be controlled with the GMP+ Feed Safety Management System and must be certified (scope Road Transport of Feed).

In the GMP+ standards (eg GMP+ B1§4.1, clause a8, or GMP+ B2 §4.4.3./TS1.2 §3.6) this is clearly stated: 'If a participant makes use of an external carrier for the transport of packaged raw materials of feed, then this external carrier (and/or freight broker) does not have to be GMP+ certified or equivalent'.

The word 'external' should be understood as 'outsourced', meaning the feed company has outsourced the transport of its packaged feed to a transport company. This transport company does not necessarily have to be certified for the transport of feed.

Please note that packaged feed and packaged products in general are not included in the IDTF. As packaged products do not come into contact with the loading compartment, there is no need to prescribe a minimum cleaning regime after transport of these products. Nevertheless, as part of tracking and tracing, each transport of packaged products must be documented/ registered in the logbook.

7.2. What are the rules for independent transport companies that are part of a multi-site organization/community?

These are the most important rules:

- Independent transport companies that are part of a multi-site organization/community must inform the main office of all feed activities. Otherwise, the main office cannot take responsibility for these transport companies.

- Everything must be assured with a contract. Invoicing can be done by a subcontractor only with an exemption

- When trade/collect locations that are part of a multi-site organization/community make use of external transport in many different countries, they can act as a gatekeeper

Road transport is permitted under multi-site certification if the road transport company involved can demonstrate that:

- the road transport company is a 100%-owned subsidiary of the main office, or

- the road transport company is part of a group of companies which have joined together as a quality community.

Besides that:

A road transport company can only be certified under multi-site requirements if the road transport company carries out all the feed activities for the main office exclusively. If this is not the case, the road transport company must be independently certified.

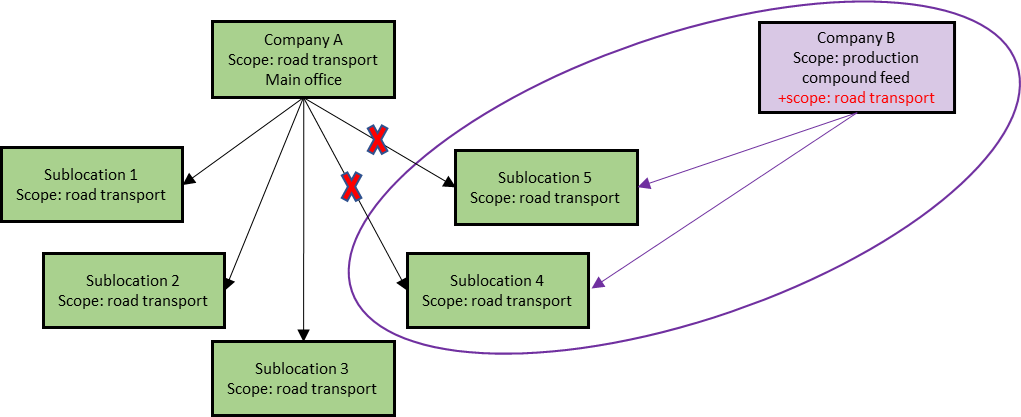

7.3. Hiring service vs. hiring company location

CASE:

Company A is certified for the scope road transport. This company is the main location in a multi-site organization with 5 sublocations.

Company B is certified for the production of compound feed. Company B hires 2 sublocations (sublocations 4 and 5), including trucks, from company A. Company B owns the following processes at sublocations 4 and 5: loading sequence planning, loading, loading tracking.

Who is responsible for the GMP+ assured transport activities at sublocations 4 and 5?

ANSWER

Company B not only hires the transport service form company A, it actually hires 2 sublocations from company A and it controls the GMP+ assured transport activities at these locations. In this case, company B must include these 2 sublocations in its own FSMS. Also, this production company must become additionally certified for the scope Road transport.

Company A is left with 3 sublocations and has no responsibility for the GMP+ assured activities at sublocations 4 and 5 anymore.

Note: Company B (compound feed producer) also needs to certified for the scope “Road transport of Feed”. If the national competent authority requires additional registration according to Reg. (EC) No 183/2005, the company should take care of this registration.

8. Other

8.1. Some guidance about the quality of water to be used

8.2. Can I also deliver GMP+ assured transport services to non-certified customers?

Yes, if a customer orders a transport of feed under GMP+ conditions, a transport company can deliver that service (also confirmed by the positive declaration) to a non-certified customer. The transport company does not have to check the certification status of the customer.

Appendix 1: Useful information about the quality of water used for cleaning loading compartments for road transport and railway transport

Water should be used in cleaning regimes B, C and D. The GMP+ FC scheme stipulates that the water should not have a negative impact on the feed safety of the feed to be transported. Inland vessels also clean using water.

The water can come from the water supply network, a spring, rainwater or possibly from open water.

Specific standards for the water used are not stipulated by the GMP+ FC scheme. GMP+ TS1.1 Prerequisite Program states that the use and safety of water should be based on a risk assessment.

What drinking water quality for cleaning loading compartments could apply to GMP+ certified companies?

For humans

There are very high standards for drinking water in the EU (Directive 98/83/EC). These standards are stricter than those used by animal health services in NW Europe.

For food-producing animals

Unlike the use of drinking water for humans, there are no EU legal requirements for drinking water for livestock. In general, EU Regulations 178/2002 and 183/2005 cover the assurance of food safety.

Quality requirements for drinking water for food-producing animals

Flanders, Germany and the Netherlands, for example, have drawn up limit values and advice for livestock drinking water in cooperation with agricultural organizations. The limit values for calves are stricter. There are a large number of parameters that apply to livestock drinking water, but for the cleaning of loading compartments these are less relevant. For example, pH, electrical conductivity, oxidisability, soluble salts. These parameters can affect corrosion of pipes in the barn, formation of a biofilm in pipes and taste.

What is relevant and important for GMP+ FC scheme?

It is important to avoid loading compartments being contaminated with undesirable organisms and/or substances when transporting feed. Biological contamination of the water can lead to the growth of microorganisms in loading compartments. This does not apply to heavy metals, pesticides, (metal) ions, anions, etc. but these substances can be toxic at elevated levels.

How can water be used for cleaning?

There are several types of water

- The safest water, without taste deviations, is tap drinking water from the network. Periodic analyzes on the quality of this water are not necessary. It is known that water with a temperature of 25° C which is stationary for more than 48 hours can pose a potential microbiological hazard.

- Spring water : shallow groundwater is less constant in quality than deep groundwater and sometimes contains more iron, salt, ammonium, nitrate and/or bacteria. In the event of contaminated piping systems and when surface water enters shallow wells, the number of germs can increase significantly.

- High levels of ammonium indicate organic contamination, for example by manure. A purification step may be necessary for shallow groundwater.

- Annual analyzes of water quality for microbiological characteristics and nitrogenous products are strongly recommended. Regular analyzes for heavy metals or pesticides are not considered necessary if historical data (analysis results, knowledge of the field, environmental authority data) do not give reason to expect increased levels.

- Rainwater contains very few salts. If the water is not stored in completely clean conditions, a biofilm can grow or bacterial cultures can develop.

- Surface water : the water quality can be (negatively) affected by many factors. For example, due to residential cores, wastewater discharges by companies, spring tides, etc.

Reuse of water ('rinse water'): a documented risk assessment (including monitoring plan) must demonstrate the safe (re)use of water. The washing water should not contain residues of cleaning and disinfectants. Treatment of this water may be necessary. The quality of the rinse water must meet the limit values that have been defined for good quality drinking water ('Tränkwasser') for food producing animals.

T aste of water

Palatability of water can be reduced at high iron content and if a so-called biofilm is created in pipes. This is a (mucus) layer created by deposits of minerals such as lime, iron and manganese, on which bacteria start to settle. Iron limit values by indication 'good': < 0.5 mg/L (GD). BMEL: < 3 mg/L.

Reference: information on quality criteria for drinking water for livestock (DE, BE, NL)

Abbreviation of consulted information from:

◌ BMEL: Federal Ministry of Food and Agriculture

◌ From: WaterPortal.be

◌ GD: Animal Health Service

…. and in feed plants + cleaning transport containers (FR)

◌ CSNA: AFCA-CIAL // Scientific Committee for Animal Nutrition

| Biological quality | ||

| Parameter | Limit value | Reference |

| Salmonella | Absent | BMEL, CSNA |

| Campylobacter | Absent | BMEL |

| E-Coli | < 10 cfu/mL | GD* |

| < 100 cfu/mL | VI | |

| Free as far as possible | BMEL | |

| Abs. in 0.1 l | CSNA | |

| Total germ count | < 10,000 cfu/mL | GD* |

| < 100,000 cfu/mL | VI | |

| < 10,000 cfu/mL (aerobic/20°C) | BMEL | |

| Yeasts and fungi | <10,000 | GD* |

| Faecal streptococci | < 1000 mg/100 ml. | GD |

| 0 cfu/100 ml | VI | |

| Sulphite reducing Clostridia | 0 cfu/20 ml | VI |

| Costridium perfringes | 0 cfu/100 ml | VI |

| Enterococci | absence in 0.1 l | CSNA |

| Sulphite reducing anaerobes | absence in 0.1 l | CSNA |

*) quality 'good' at GD

▻ Microbiological analysis according to CSNA must be carried out at least once a year.

| Chemical quality | ||

| Parameter | Limit value | Reference |

| Pesticides: plant protection products | < 0.1 μg/L | GD |

| EU Directive no. 2002/32 | CSNA | |

| Heavy metals: | | |

| Pb | < 0.1 mg/L | BMEL |

| | EU Directive no. 2002/32 | CSNA |

| As | < 0.05 mg/L | BMEL |

| | EU Directive no. 2002/32 | CSNA |

| Cd | < 0.02 mg/L | BMEL |

| | EU Directive no. 2002/32 | CSNA |

| Hg | < 0.003 mg/L | BMEL |

| | EU Directive no. 2002/32 | CSNA |

| Nitrogen and sulphur-containing products: | | |

| Ammonia | < 2 mg/L | GD* |

| | < 2 mg/L | BMEL |

| Nitrate | < 100 mg/L | GD* |

| | < 200 mg/L | BMEL |

| | < 200 mg/L | VI |

| Nitrite | < 0.1 mg/L | GD* |

| | < 30 mg/L | BMEL |

| | < 1 mg/L | VI |

| Sulphate | < 100 mg/L | GD* |

| | < 500 mg/L | BMEL |

*) quality 'good' at GD